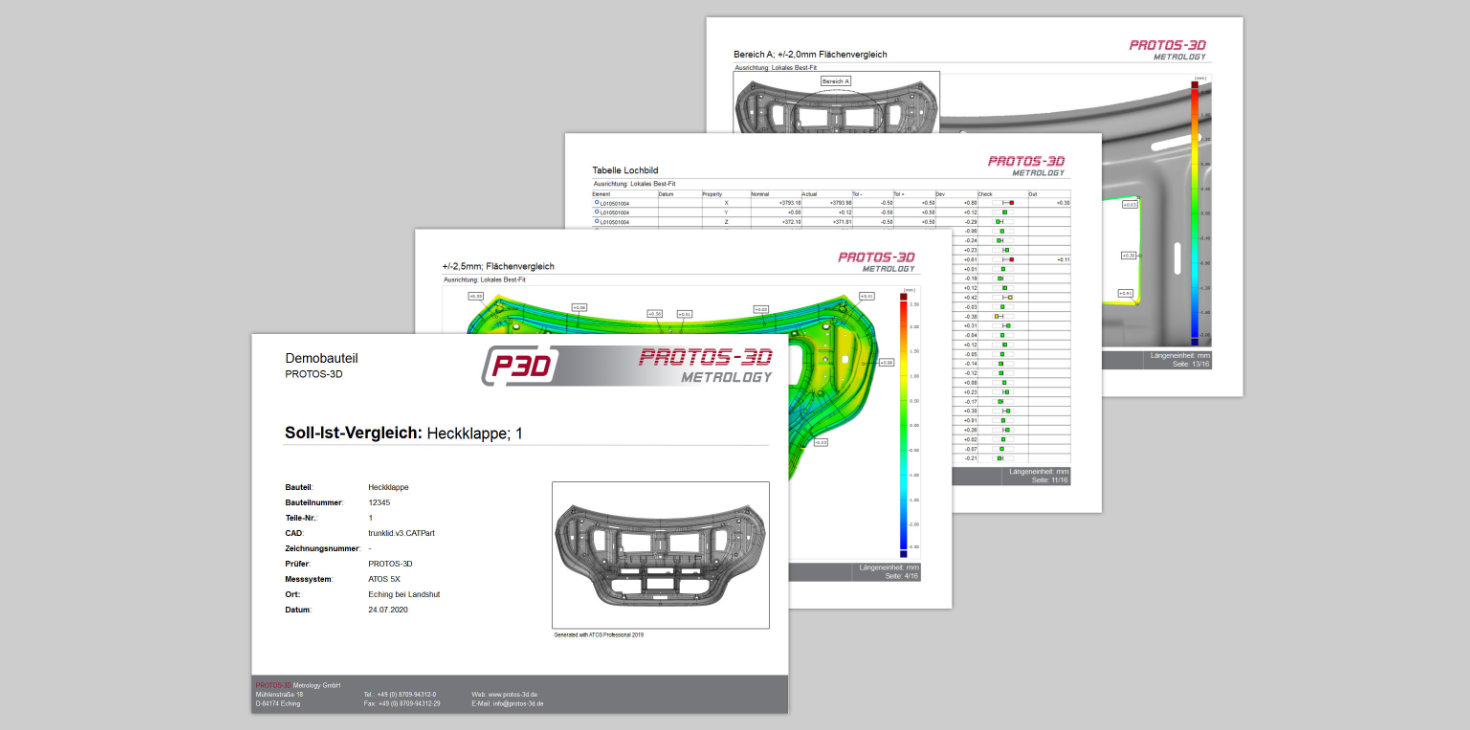

Analysis / Measuring report

The measuring report with the special touch!

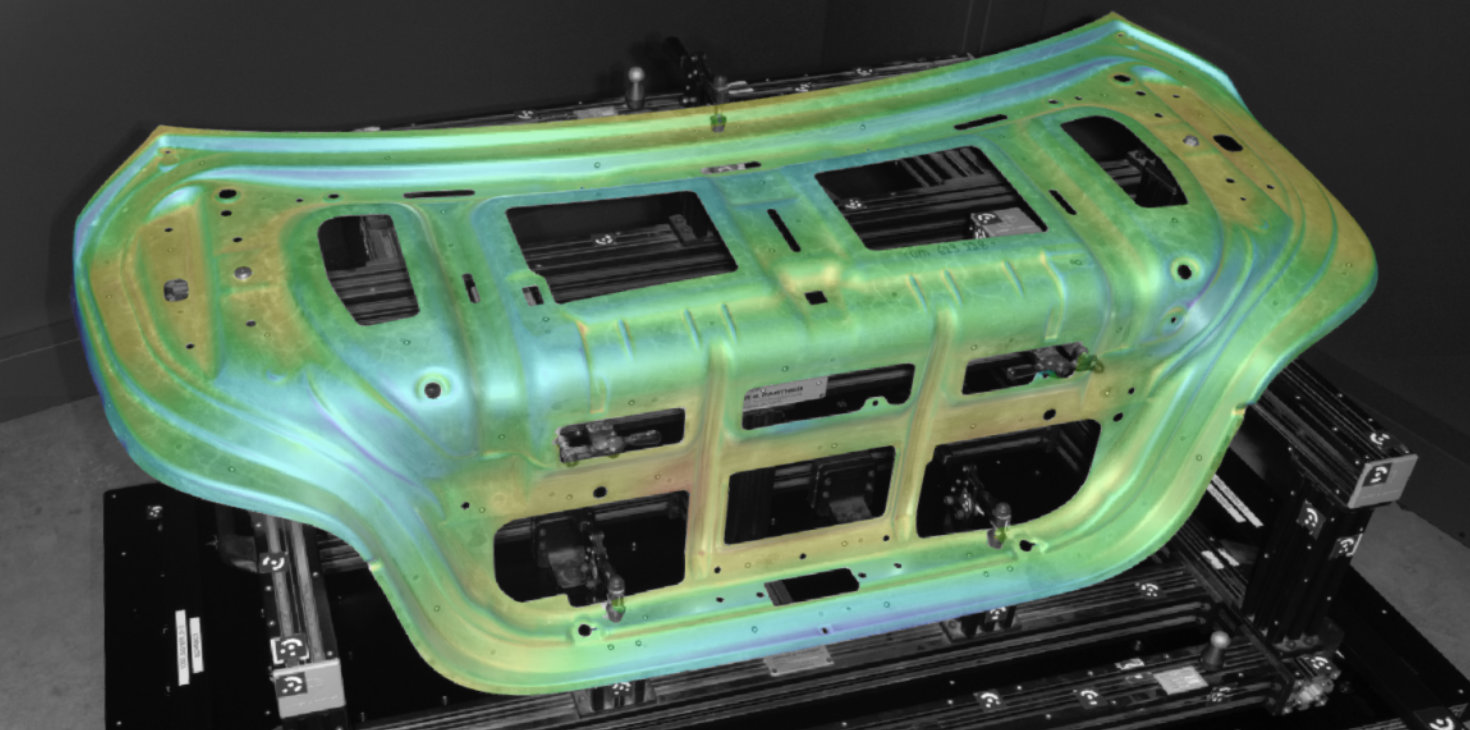

The visualization of the measurement results takes place in a 3D measuring report.

A full-surface geometrical and dimensional analysis incl. a comparison against CAD is possible as well as an export of tables and reports with CMM inspection points.

By doing so, we create an optimal basis for your component evaluation. For an easy and compact exchange of measurement results and further analyses, the free GOM Inspect software is also available. Another benefit is the possibility of automated evaluations. This allows component series to be analyzed quickly and consistently.

Analysis possibilities

Surface comparison / comparison against CAD

Measurement plan import and export

Measurement and feature evaluation according to specified measurement plan. Transfer of the measurement results in the form of the measurement plan format, e.g. BMW IPP, Pi-Web, or similar, for import into the respective company’s own statistical software for further processing and analysis.

Surface wall thickness visualization

Virtual wall thickness analysis – determination of the wall thickness based on the measured data as well as visualization of the result by means of a color deviation plot.

Evaluation according to technical drawing

Feature evaluation according to drawing specification

Possible for multiple alignments in one project, e.g. Best-Fit, RPS, Plane-Line-Point, ...

All standard alignment functions can be implemented. This includes:

RPS alignment, hierarchical alignment based on geometry elements, alignment in a local coordinate system, via reference points, and various best-fit methods such as global and local best-fit. In addition, customer-specific alignments can be made.

Geometric Dimensioning and Tolerancing, e.g. roundness, flatness, position, squareness, ...

Hole positions and geometries

Trim points and springback

Immediate inspection for geometrical and dimensional accuracy. Distortion, shrinkage and sink marks on injection molded or cast parts, as well as springback, trimming and bounce on sheet metal parts, are made particularly clear.

Inspection sections

Surface Defects Analysis

The digital whetstone method allows easy visualization of surface defects and imperfections, such as dents, sink marks, dings, scratches, adhesive residue and weld spatter. Surface defect classification according to your own specifications is also possible.

Initial sample inspection reports

Initial sampling is a testing and verification process to ensure that a product has been manufactured in accordance with engineering drawings, Digital Product Definition (DPD), planning, purchase order, technical specifications, and/or other applicable design document. The initial sample inspection report provides a statement as to whether the parts meet the requirements, need to be reworked, or even need to be newly produced. Furthermore, conclusions can be drawn about tools to be changed in order to achieve the required component geometry.

Trend, SPC (static process control) and deformation analyses

Questions?

We analyse.

You profit.

How can we support you? Contact us and we will get back to you as soon as possible.

Sorry, no posts matched your criteria.